Share this

Using Building Analytics To Weigh Repairing vs. Buying New Equipment

by Ron Rau on May 18, 2020

In our last few posts, we've been looking at best practices on maintaining building equipment. Our posts Be Strategic with Building Scheduled Maintenance and How To Test The Quality Of Your Preventative Maintenance look at how to get the most out of equipment maintenance. In this post, we will look at how you can use data to evaluate whether to replace or repair equipment, even while a technician is on site.

Equipment Replacement Strategy

There is a balancing act involved when you evaluate your equipment. Primarily you are weighing the cost of a new purchase against preventative maintenance (PMs) and/or repairs, book value (if any),energy savings, and expected life of the equipment. We recommend using a worksheet, much like our HVAC Replacement Strategy worksheet, to help determine whether to replace or repair a piece of equipment. You can quickly make such determinations with the right data and tools to calculate.

Below are some of the basic points from our HVAC worksheet, although the methodology can be used when weighing repair vs. replace on any piece of equipment.

The goal is to develop a ranking system, from best to worst, that you can judge all your units by. In this way, you can prioritize the lowest ranking units (which really need fixing) and see opportunities to proactively bulk buy equipment or parts.

Maintenance Program Options & Implementing A Predictive Program

Pro-active Equipment Replacing and Pre-buying

Along with the above ranking strategy, you should have vendors survey equipment each year and take strategic photos of units. Where your equipment ranks, along with the photographic evidence, correlates to a life expectancy of the unit.

Recommended strategic shots of equipment include pictures of the:

- Unit nameplate

- Control section

- Profile shot showing two sides with condensate drain

- Profile shot showing two sides with condenser coil condition

- Evaporator/filter section showing condition of evaporator coil

- Fan section showing belt and pulley

- Compressor section showing compressor piping (if a compressor was replaced)

With data like this at your fingertips, you can be proactive with replacements. For example, if you notice that there are a high number of units that fall in the replacement category, you can pre-buy (with potential bulk buying savings) and strategically store those units around the country. This can save significantly on the downtime involved when reactively purchasing replacements and getting them to a required location. It is not uncommon for replacement units to take up to 3 weeks from order to install.

Downtime can lead to:

- Impacts on energy usage - faulty units pull more energy.

- Impacts on occupant comfort - from customers to employees, depending on the time of year, occupants may be extremely uncomfortable.

- Higher costs - when you reactively buy, you limit the discounts you can take advantage of, such as with bulk or end-of-year purchasing.

- Higher installation costs - reactive installs can cost more depending on how busy techs are, time of year, etc. Proactive planning can help you take advantage of cheaper installation costs.

Units and Install Price Reductions

When you pre-buy units, you can proactively schedule installs. If you can plan for February installs, for example, you can usually secure much lower labor rates because you are keeping technicians busy during regular downtimes. In fact, negotiating these sorts of installs along with bulk buying can give you quite a bit of leverage with vendors. You will be able to do more with the budget you have by being proactive.

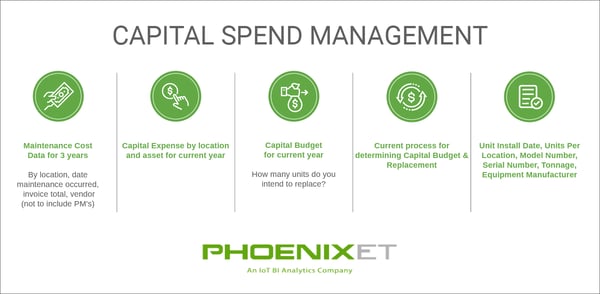

Capital Budget Requests

There can be a number of capital spend versus expense criteria involved on equipment. That is why ranking units helps as it gives you a clear picture of the lifelong value on a unit. And rankings help you communicate monetary value to those authorizing budgets.

Calculating Depreciation

The value left on units is important to take into account as well. Let's say you have a four-year-old HVAC unit that you wish to replace. You need to account for the cost of the new equipment plus the value still on the books.

If the four-year-old unit replacement is going to cost $30,000, but there is $10,000 still on the books all up, you are going to take a hit of $40,000.

Calculating ROI

Now let's say you decide to replace parts instead of replacing the four-year-old HVAC unit. But your technician determines that you are replacing parts that are going to just break again due to the age of the unit and the fact that it cannot run as efficiently as it should. If you can calculate repeat costs and the drain on utilities an inefficient unit will cause, you can overview the true ROI and make better determinations on repair vs. replacement.

Pulling It All Together

If you have the data to do these calculations, you will be able to prove what the right cost-savings decisions are to budget authorizers. When your PMs are streamlined, proactive purchasing and installing costs are at play, and you weigh all the value points, you can show how cost reductions will occur despite higher preventative and proactive spending.

Be sure to download our HVAC replacement worksheet below for a really good example of the types of replacement criteria, ROI calculations, and HVAC unit information to consider when deciding on replacement vs. repairing.

Additional Resources:

Why Setpoint is not The Zone Temp

Don't Wait For Building Upgrades To Save Money On Energy

How To Test The Quality Of Your Preventative Maintenance

4 Common Myths of Energy Conservation in Building Management

Share this

- Facilities Management (91)

- Energy Management (69)

- Company News (49)

- Smart Buildings (37)

- Retail (36)

- Building Management (24)

- Building Automation Systems (21)

- Sustainability (20)

- Energy Demand Management (19)

- EEI (15)

- Adaptive Energy Management (14)

- Grocery (14)

- demand response (14)

- Artificial Intelligence (12)

- Data Integration and Visibility (10)

- HVAC IQ (10)

- COVID-19 (8)

- Customer Spotlight (8)

- Carbon Management (7)

- Refrigeration Optimization (7)

- Setpoints and Temperatures (7)

- Equipment Maintenance (6)

- Operational Efficiency (6)

- Ask Ron (5)

- Asset Manager (5)

- Finance and Procurement (5)

- IoT and Digital Transformation (5)

- Awards (4)

- Comfort (4)

- Energy & Store Development (4)

- Safety and Compliance (4)

- Demand Charge Management (3)

- Energy Management System (3)

- Lifecycle Asset Management (3)

- Premium Services (3)

- Refrigeration IQ (3)

- Automated Demand Response (2)

- ConnexFM (2)

- Customer Service (2)

- HVAC Vendor Management (2)

- Load Shedding (2)

- Technician View (2)

- AIM Act (1)

- ALD (1)

- Analytics (1)

- Commissioning (1)

- Data (1)

- Data Integration and Visualization (1)

- EMS (1)

- Knowledge Center (1)

- OSHA (1)

- asset management (1)

- January 2026 (1)

- December 2025 (1)

- November 2025 (1)

- October 2025 (2)

- September 2025 (1)

- August 2025 (3)

- July 2025 (1)

- June 2025 (1)

- May 2025 (2)

- March 2025 (2)

- February 2025 (1)

- January 2025 (2)

- December 2024 (2)

- October 2024 (1)

- September 2024 (1)

- August 2024 (2)

- June 2024 (2)

- April 2024 (2)

- March 2024 (2)

- January 2024 (1)

- December 2023 (1)

- October 2023 (2)

- September 2023 (2)

- August 2023 (2)

- July 2023 (1)

- May 2023 (2)

- April 2023 (2)

- March 2023 (3)

- February 2023 (1)

- January 2023 (1)

- December 2022 (1)

- November 2022 (2)

- October 2022 (2)

- September 2022 (1)

- May 2022 (2)

- April 2022 (1)

- March 2022 (3)

- February 2022 (2)

- January 2022 (4)

- December 2021 (2)

- November 2021 (3)

- October 2021 (1)

- September 2021 (3)

- August 2021 (4)

- July 2021 (1)

- June 2021 (2)

- May 2021 (1)

- January 2021 (2)

- December 2020 (2)

- November 2020 (2)

- October 2020 (3)

- September 2020 (4)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (3)

- April 2020 (5)

- March 2020 (5)

- February 2020 (4)

- January 2020 (4)

- December 2019 (4)

- November 2019 (3)

- October 2019 (4)

- September 2019 (5)

- August 2019 (4)

- July 2019 (4)

- May 2019 (2)

- April 2019 (3)

- February 2019 (1)

- December 2018 (1)

- November 2018 (1)

- October 2018 (3)

- September 2018 (3)

- August 2018 (3)

- July 2018 (3)

- June 2018 (3)

- May 2018 (1)

- June 2015 (1)

- March 2013 (1)

- January 2013 (1)

- December 2011 (1)

- October 2011 (1)

- September 2011 (1)